- 22% reduction in spoilage, saving a lot annually

- Traceability reporting time cut from 48 hours to under 5 minutes

- 5-point gross margin improvement through data-driven pricing

Background

Nacharmagevi is one of Georgia’s premier poultry producers, a vertically integrated company with a profound civic responsibility: supplying high-quality, safe chicken products to public organizations, including the nation’s kindergartens. Managing the entire production lifecycle—from its own hatcheries and feed mills to modern processing plants—is central to their promise of delivering safe and reliable food to a vulnerable population.

This “farm-to-fork” control was Nacharmagevi’s greatest strength but also the source of immense operational complexity. As the company grew, its reliance on outdated, disconnected systems and manual processes created significant cracks in its foundation. The tools that had supported its initial growth were now hindering its ability to scale, manage risk, and maximize profitability. Nacharmagevi’s leadership knew a fundamental digital transformation was a necessity for survival and future dominance.

The Challenge

Nacharmagevi’s operational challenges were rooted in a lack of unified data, creating costly inefficiencies that rippled across the organization.

Perishable Inventory in a Digital Black Hole: The company’s most critical asset—its perishable inventory—was its biggest liability. With separate ledgers, enforcing a strict First-In, First-Out (FIFO) system was impossible. This caused significant, preventable spoilage—a direct drain on revenue. The warehouse was a maze of manual logs, preventing an accurate, real-time picture of stock levels and leading to both costly overproduction and sales-killing stockouts.

A Ticking Clock on Traceability: In the food industry, traceability is non-negotiable. With fragmented systems, tracing a single batch from a customer back to its flock and feed lot was an all-hands-on-deck manual exercise that took up to 48 hours. This exposed the company to unacceptable financial, legal, and reputational risk, jeopardizing its hard-won contracts with major retailers.

Invisible Profitability and Inaccurate Costing: The company couldn’t answer a fundamental question: what is the true cost of our products? Without a system to accurately allocate the costs of feed, veterinary supplies, and labor across different flocks and cuts, profitability was a mystery. They couldn’t definitively know the margin differences between products or customer segments. This left pricing decisions to instinct, leaving money on the table.

Operational Drag and Financial Delays: The finance department was buried in manual work, re-entering data to close the books, a process taking nearly two weeks each month. By the time management received reports, the information was too old to be actionable. Furthermore, managing dual units of measure (e.g., buying in tons, using in kilograms; tracking live birds by “head,” selling by weight) created a constant source of errors.

Our Approach

Stemscale approached this transformation with a methodical plan to replace Nacharmagevi’s fragmented processes with a single, intelligent digital core, leveraging our signature Diagnose–Design–Deliver framework.

Diagnose

We began with a deep, immersive analysis of Nacharmagevi’s entire value chain, spending time on-site from the hatchery to the finance office. We mapped critical workflows from procurement to distribution, identifying the precise points of failure. This created a data-driven case for change that aligned the entire leadership team.

Design

Using diagnostic insights, we architected a comprehensive solution. We selected a cloud-based ERP with a specialized Process Manufacturing module, essential for the food industry. The system was designed to solve their biggest challenges head-on:

- Granular Inventory and Costing Engine: The system featured full lot-number and batch tracking to enforce FIFO logic automatically. We then built a sophisticated activity-based costing model to allocate all production costs, revealing the true profitability of every product.

- End-to-End Traceability Framework: The solution linked every element of the supply chain, allowing instant traceability from a finished product back to its specific flock and feed lot.

- Unified Operational Platform: We designed workflows to seamlessly handle dual units of measure and integrated mobile warehouse management (WMS) with barcode scanning to ensure 99%+ accuracy.

Deliver

Our delivery phase was meticulously planned for a seamless transition.

- Data Foundation: We started by cleansing and migrating years of critical data—from supplier contracts to product specifications—to build the new system on a bedrock of clean, reliable information.

- Phased Implementation: We rolled out the system in logical phases, starting with inventory and production, followed by finance and sales, to manage risk and build momentum.

- Role-Based Training: We conducted extensive, role-specific training for all user groups to ensure immediate and confident adoption across the company.

The Impact

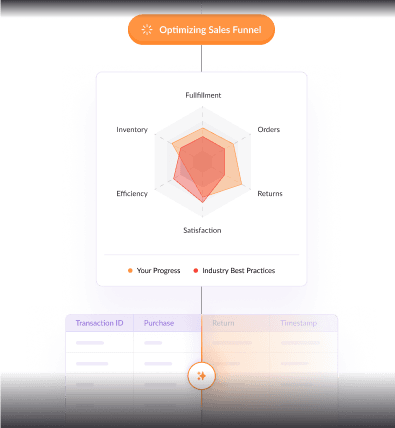

The shift from manual guesswork to a unified, data-driven operation delivered transformative and measurable results, strengthening Nacharmagevi’s market leadership and financial health.

Dramatically Reduced Waste and Unlocked Capital:

- 22% reduction in spoilage within nine months due to system-enforced FIFO logic, saving the company six figures annually.

- Optimized procurement and production planning led to a 20% reduction in inventory carrying costs.

Fortified Food Safety and Brand Reputation:

- Traceability reporting time was cut from 48 hours to under 5 minutes, providing ironclad security and solidifying trust with major retail partners.

Achieved True Profit Visibility and Growth:

- A 5-point gross margin improvement was realized through data-driven pricing strategies based on accurate, real-time product costing.

- Management could now analyze profitability by customer, region, and product line, enabling a more effective sales strategy.

Created Strategic and Operational Agility:

- The month-end financial close was accelerated from 12 days to just 3, providing management with timely, actionable intelligence.

What We Delivered

Stemscale provided Nacharmagevi with a powerful, end-to-end digital platform that serves as the foundation for its next generation of growth:

- A Cloud-Based ERP with a Specialized Process Manufacturing Module designed for the complexities of the industry.

- An End-to-End Traceability and Quality Control System providing farm-to-fork visibility for every batch.

- An Integrated Warehouse Management System (WMS) with mobile barcode scanning for 99%+ inventory accuracy.

- A Sophisticated Activity-Based Costing Model for true product and customer profitability analysis.

- A Unified B2B Sales Management Module for handling complex contracts and pricing with major retailers and HoReCa clients.

- A Comprehensive Change Management and Training Program that ensured confident user adoption and a successful, long-term partnership.