• 15% higher profit margins despite a 20% reduction in harvest volume

• 30% cut in cost per bulb through streamlined, data-driven operations

• 100% regulatory compliance with zero quality compromise

• Premium market positioning achieved, turning ethics into a competitive edge

Background

Eco Plants LLC is a leading sustainable horticulture company in Georgia, specializing in snowdrop bulbs (Galanthus woronowii) and rare plant seeds. As one of the country’s primary licensed exporters of snowdrop bulbs, Eco Plants has long been committed to ethical sourcing and environmental stewardship. In Georgia, around 15 million snowdrop bulbs are harvested annually, and Eco Plants alone holds rights to nearly 33.33% of the national harvest quota. This outsized role goes hand-in-hand with outsized responsibility: from ensuring fair wages for local bulb harvesters to complying with strict conservation rules. In an industry where villagers typically earn only about $1.6 per thousand bulbs collected while the same bulbs retail for over $1,140 per thousand in western markets, Eco Plants has prided itself on going above and beyond. The company channels its sustainability ethos into every level of operations, striving to give back more than it takes.

However, at some point Eco Plants found itself at a crossroads. The global demand for ethical, sustainable products was rising – a trend very much in the company’s favor – yet so were the pressures on its business model. Years of stable growth under a weight-based harvesting fee system were about to change dramatically. New regulations were poised to alter the entire fee structure for snowdrop bulb exports, potentially upending Eco Plants’ hard-won competitive position.

The Challenge

The challenges hit Eco Plants from multiple angles, all at once. First, a regulatory shift changed the game: the government moved from a weight-based fee for harvested bulbs to a per-unit harvesting fee structure. Previously, export licenses and extraction fees were calculated per kilogram of bulbs – a system that hadn’t changed since 2006 – but now every individual bulb carried a cost. This seemingly subtle change had an enormous impact. Overnight, the company’s cost per bulb skyrocketed, regardless of bulb size or weight. Harvesting smaller bulbs (which weigh less) was no longer economical, forcing Eco Plants to leave a larger portion of the crop in the ground. The result: lower yields by volume. Yet sacrificing quality was not an option for a company devoted to sustainability; Eco Plants refused to simply harvest everything and anything to make up the difference. They needed to maintain their premium quality standards and ethical harvesting practices (leaving sufficient bulbs to regenerate wild populations) despite collecting fewer bulbs overall.

At the same time, these higher regulatory fees squeezed margins that were already tight. Eco Plants’ dedication to fair pay and sustainable methods meant their operating costs ran higher than competitors who might cut corners. Now, with a per-bulb levy increasing costs further, the company risked slipping from black into red. The CEO, Simon Tatoshvili, encapsulated the situation: “We suddenly had to pay for each bulb as if it were gold. It threatened to make our most principled decisions – like paying harvesters fairly and selecting only mature bulbs – feel like liabilities rather than strengths.” In short, Eco‑Plants had to reinvent its competitiveness under new conditions. How could they continue to thrive commercially while staying true to their ethos? The challenge spanned strategic and operational dimensions: rethink the pricing model, boost internal efficiency to offset costs, adapt to fee hikes, and do it all without compromising on quality or ethics. It was a high-stakes balancing act between profit and principle

Our Approach

We partnered with Eco Plants to turn this inflection point into an opportunity.

- Phase 1: Strategic Refocus. We kicked off with a deep dive into Eco Plants’ financial and market position. By performing a comprehensive competitiveness audit, we helped the company rethink its value proposition in light of the new fee structure. Rather than competing on sheer volume (no longer viable with yields down), Eco Plants would lean into differentiation. Data showed that global buyers were increasingly willing to pay a premium for ethically sourced, high-quality botanical products – indeed, 84% of business leaders believe that embedding ethics into operations can be a route to competitive advantage. We helped Eco Plants capitalize on this trend.

- Phase 2: Efficiency and Process Innovation. Next, we zeroed in on operational efficiency to improve margins from the inside out. Our team, including experts in process mining and agricultural analytics, mapped out every step of Eco Plants’ harvest and production workflow – from field collection to sorting, packing, and export logistics. What we found were several bottlenecks and legacy practices ripe for improvement. Together with Eco Plants management, we introduced a series of lean process changes and smart automation:

- Harvest Optimization: We developed a scheduling and tracking system to ensure the optimal timing and rotation of bulb collection. By using digital field data (like soil and weather conditions), harvesters could target plots when yields and bulb size were at their peak, mitigating the volume loss. Every bulb picked was a bulb that justified its cost.

- Waste Reduction: We implemented a real-time inventory and grading application to sort bulbs more efficiently. Bulbs that didn’t meet Eco Plants’ quality threshold (too small or damaged) were now identified instantly and either replanted or repurposed (for example, sold as bulk ornamental bulbs for local landscaping) rather than accidentally shipped and rejected later. This cut down waste and saved money.

- Process Automation: We streamlined packing and processing using affordable automation tools. Manual handling steps were reduced – freeing up 30% of staff time – and error rates in order fulfillment dropped sharply. The new system also improved traceability, so Eco Plants could confidently market its transparency (each shipment now came with a sustainability report).

The Impact

The impact of these interventions was quickly evident – both in the numbers and in less tangible ways. Operational efficiency soared. By eliminating bottlenecks and waste, Eco Plants slashed its cost per bulb by about 30%, directly offsetting the new regulatory fees. What could have been a fatal blow to margins turned into a catalyst for leaner operations. Despite harvesting around 20% fewer bulbs than the previous season, Eco Plants actually saw a 15% increase in gross profit margins year-on-year, thanks to better pricing and cost control. The company successfully navigated the switch to per-unit fees with zero disruption to customer orders or delivery timelines. In fact, several European clients, impressed by the company’s transparency and consistent quality, signed multi-year contracts at the new, higher price point – a strong validation of the competitive strategy. Eco Plants effectively turned its principles into a market advantage, proving that sustainability and profitability can grow hand-in-hand.

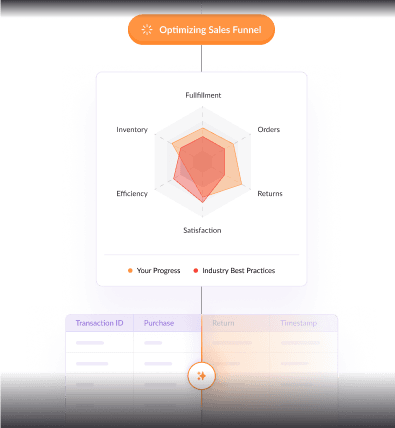

Quality metrics also held strong. The average bulb size and health rating in exports improved (no more bags weighed down with undersized bulbs just to meet old weight targets), and customer satisfaction scores nudged upwards. Internally, the enhanced processes meant that every department, from field operations to logistics, was working in sync with real-time data. The company became more agile, able to adjust to any further regulatory tweaks or market shifts swiftly using the dashboard and analytics tools we provided.

Perhaps the best testament to the transformation came from Eco Plants’ own CEO. “We didn’t just adapt to the new rules – we mastered them, says Simon Tatoshvili, the CEO. In one season, we improved our margins and proved that our uncompromising ethical approach is our competitive edge. I’ve never seen our team so motivated and our customers so engaged.”

This renewed momentum has positioned Eco Plants as a role model for sustainable enterprise in the region, reinforcing that doing good and doing well are not mutually exclusive.

What We Delivered

- Sustainable Competitiveness Strategy: A complete rethinking of Eco Plants’ market positioning and pricing, highlighting their ethical and sustainable strengths to justify premium pricing and secure long-term buyer loyalty.

- Process Optimization: End-to-end streamlining of the bulb harvest and processing workflow, including the introduction of digital tracking for harvest yields, automated sorting and packing systems, and elimination of inefficiencies (resulting in significant cost savings and faster turnaround times).

- Data & Analytics Tools: Implementation of custom dashboards and KPIs for Eco Plants’ management, enabling real-time monitoring of harvest volumes, quality grades, costs, and revenues – critical for making quick, informed decisions under the new fee structure.

- Resilience Roadmap: A forward-looking plan outlining how Eco Plants can continue to innovate (such as exploring selective cultivation of snowdrops, expanding the rare seeds portfolio, and investing in further automation) to stay ahead of regulatory changes and market trends.

By delivering these five pillars, we didn’t just solve an immediate problem – we empowered Eco Plants with the tools and mindset to thrive in the long run. In the face of a major industry shift, Eco Plants emerged more competitive, more efficient, and more sustainability-driven than ever, demonstrating that a company truly rooted in ethics can bloom even in the toughest conditions.